plating thickness tester wikipedia|hard chrome plating thickness tester : bespoke Classification societies have detailed requirements for the thickness measurement of hull structures. These requirement depend . See more WEB155 Hotel. Rua Martinho Prado, 173, Consolação, São Paulo, CEP 01306-040, Brazil – .

{plog:ftitle_list}

We have researched it for you! The reliability we are looking for is, of course, primarily in the presence of a license. At N1 Casino we have found a license from the . Ver mais

In the field of industrial ultrasonic testing, ultrasonic thickness measurement (UTM) is a method of performing non-destructive measurement (gauging) of the local thickness of a solid element (typically made of metal, if using ultrasound testing for industrial purposes) based on the time taken by the ultrasound wave to . See moreAn ultrasonic thickness gauge is a measuring instrument for the non-destructive investigation of a material's thickness using See more• Usually requires calibration for each material• Requires good contact with the material• Cannot take measurement over rust (Does not apply to . See more

Classification societies have detailed requirements for the thickness measurement of hull structures. These requirement depend . See more

• Non-destructive technique• Does not require access to both sides of the sample• Can be engineered to cope with coatings, linings, etc. See moreUTM is frequently used to monitor metal thickness or weld quality in industrial settings such as mining. NDE technicians equipped with portable UTM probes reach steel plating in sides, . See more

The Calo tester, also known as a ball crater or coating thickness tester, is a simple and inexpensive piece of equipment used to measure the thickness of coatings. Coatings with thicknesses typically between 0.1 to 50 micrometres, such as Physical Vapor Deposition (PVD) coatings or Chemical Vapor Deposition (CVD) coatings, are used in many industries to improve the surface propertie.

The best way to measure and verify the thickness of a heavy build up plated layer is by using a combination of X-Ray Fluorescence (XRF) and Eddy Current Testing (ECT). . Controlling the thickness of the plating layer is done through precise process control and monitoring. Factors such as the concentration of metal ions in the plating solution, . Paint and coating thickness is determined by measuring this pull-off force. Thinner coatings will have stronger magnetic attraction while thicker films will have comparatively less magnetic attraction. Testing with magnetic .

High-precision measuring devices for coating thickness measurement, material analysis, nanoindentation and material testing from the technology leader. We are your reliable partner in the field of surface testing.Handheld coating thickness and inspection instruments: Adhesion, Dew Point, Surface Profile, Salt Contamination, Wall Thickness, Porosity, Shore Hardness and more . ultrasonic wall thickness gage, or hardness tester; Select from .A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .

This pen-shaped gauge is good for use on hard-to-reach surfaces and comes with a calibration certificate traceable to NIST that states it has passed a test for accuracy. Wet-Coating-Thickness Gauges Measure the thickness of wet coatings such as paint.The most common industrial test for cleanliness is the waterbreak test, in which the surface is thoroughly rinsed and held vertical. . In a Haring-Blum cell, for example, L = 5 for its two independent cathodes, and a cell yielding plating thickness ratio of M = 6 has Harring-Blum throwing power 100% × (L − M) / L = −20%. [9]The PosiTector 200 Ultrasonic Coating Thickness gage non-destructively measures a wide variety of applications using proven ultrasound technology. Measure paint and coating thickness over wood, concrete, plastic, and more. Advanced models measure up to 3 layers with graphics. Conforms to ASTM D6132 and ISO 2808.

The salt spray test (or salt fog test) is a standardized and popular corrosion test method, used to check corrosion resistance of materials and surface coatings.Usually, the materials to be tested are metallic (although stone, ceramics, and polymers may also be tested) and finished with a surface coating which is intended to provide a degree of corrosion protection to the underlying .An IBM circuit board from a NASA Space Shuttle computer with a conformal coating applied. Conformal coating is a protective, breathable coating of thin polymeric film applied to printed circuit boards (PCBs). Conformal coatings are typically applied with 25–250 μm [1] thickness on electronic circuitry to protect against moisture and other substances. .

The Triplett Model CTT42 Coating Thickness Tester uses smart automatic recognition of ferrous (magnetic induction) and non-ferrous (eddy current measurement) substrates. Ideal for paint shops and electroplaters, chemical, automobile, shipbuilding, and aircraft industries. Use in the laboratory, workshop, or field. ReadIt fulfils a long standing need on the market for reliable, accurate & Economical Plating Thickness Tester for all type of Plating. There is no separate cost for each PBC Plug. Model -Ptt Eco. Specifications: Principle: Coulometric: Type: Destructive: Measuring Range: 00.1 to 99.9 microns: Resolution: 0.1micron:Lacquer being sprayed onto a cabinet. A coating is a covering that is applied to the surface of an object, or substrate. [1] The purpose of applying the coating may be decorative, functional, or both. [2] Coatings may be applied as liquids, gases or solids e.g. powder coatings.. Paints and lacquers are coatings that mostly have dual uses, which are protecting the substrate and being .Printed circuit board of a DVD player Part of a 1984 Sinclair ZX Spectrum computer board, a printed circuit board, showing the conductive traces, the through-hole paths to the other surface, and some electronic components mounted using through-hole mounting. A printed circuit board (PCB), also called printed wiring board (PWB), is a medium used to connect or "wire" .

Calo tester: coating thickness test; Nanoindentation: hardness test for thin-film coatings; Pin-on-disc tester: wear and friction coefficient test; Scratch tester: coating adhesion test; X-ray micro-analyzer: investigation of structural features and heterogeneity of elemental composition for the growth surfaces [6]Electrostatic coating is a manufacturing process that employs charged particles to more efficiently paint a workpiece. Paint, in the form of either powdered particles or atomized liquid, is initially projected towards a conductive workpiece using normal spraying methods, and is then accelerated toward the work piece by a powerful electrostatic charge.All New Elcometer 456 Top Ferrous metal substrate coating thickness gauge with integral probe. Range: 0-60 mils. Memory stores up to 150,000 readings in up to 2500 batch files that are each capable of storing a distinct calibration. Three .

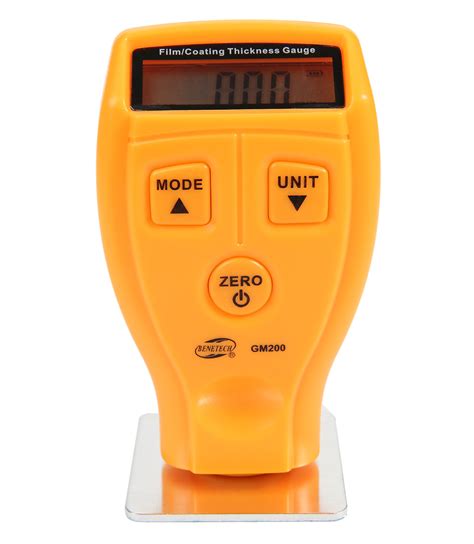

A coating thickness gauge, also known as a paint thickness gauge or a film thickness gauge, is a specialized instrument used to measure the thickness of coatings applied on various surfaces. It plays a crucial role in .The Triplett Model CTT47 Coating Thickness Tester with USB uses smart automatic recognition of ferrous (magnetic induction) and non-ferrous (eddy current measurement) substrates. Ideal for paint shops and electroplaters, .An eddy current thickness gauge measures the thickness of non-conductive coatings on non-magnetic substrates such as copper, aluminum, and brass. ECT gauges detect common coating defects, including corrosion, cracking, .

Eddy current testing (ECT) as a technique for testing finds its roots in electromagnetism. Eddy currents were first observed by François Arago in 1824, but French physicist Léon Foucault is credited with discovering them in 1855. ECT began largely as a result of the English scientist Michael Faraday's discovery of electromagnetic induction in 1831. . Faraday discovered that .Machine parts with electroless nickel plating. Electroless nickel-phosphorus plating, also referred to as E-nickel, is a chemical process that deposits an even layer of nickel-phosphorus alloy on the surface of a solid substrate, like metal or plastic.The process involves dipping the substrate in a water solution containing nickel salt and a phosphorus-containing reducing .

The coating thickness is often between 5 μm and 15 μm, with thicker layers also possible where there are special requirements. . In salt spray tests zinc flake coatings demonstrate better protection against corrosion than a typical galvanic zinc coating, which in the tests (generally run in accordance with ISO 9227) often achieve only 96 .Universal coating thickness gauge utilising the wedge cut method to measure organic coatings on metal, wood and synthetic material. Price ,991.04. View Details. 3000EZ Series. Coating Thickness Gauge for General Purpose Applications. Measuring Range: Ferrous: 0 .The Elcometer 456 Dry Film Thickness Gauge, also referred to as a Paint Thickness Meter, is available in three different models. Each coating thickness gauge provides the user with increasing functionality - from the entry level Elcometer .Plating is a finishing process in . available offering over 5 times the protection of conventional zinc plating and up to 1,500 hours of neutral salt spray test performance. This plating is a combination of a high-nickel zinc-nickel alloy (10–15% nickel) and some variation of chromate. . offers a long list of technical advantages such as .

A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.A coating thickness gauge is an essential quality assurance tool when anodizing, galvanizing and applying zinc coating to metallic surfaces. A coating thickness gauge also is used to measure body paint thickness and uniformity on pre-owned cars, revealing repainted spots, identifying hidden damages and exposing undisclosed accidents.Manufacturer of Plating Thickness Tester - Advance Micro Test, Zinc Test Micro Probe, ADVANCE WIRE CELL THICKNESS TESTER and Ptt-eco Thickness Tester offered by Kiran Electronics, Ambarnath, Maharashtra. Kiran Electronics. Ambernath, Ambarnath, Thane, Maharashtra. GST No. 27AJDPA3068N1Z4.

precise coating thickness gauge

This pen-shaped gauge is good for use on hard-to-reach surfaces. Use it to measure nonmagnetic coatings such as paint, galvanizing, plating, and enamel on steel. This gauge displays readings in mils and microns. For readings in mils, one mil equals 0.001". It comes with a calibration certificate traceable to NIST that states it has passed a test for accuracy.

plating thickness tester price

plating thickness measuring instrument

Find the best offers and Promotions at Napoleon Games for c.

plating thickness tester wikipedia|hard chrome plating thickness tester